Business

Mic’s approach

As a professional of manufacturing, we attend to our duties by making use of our past technique

and experience,

and at the same time enlarging the mind to chart our future course with a broad perspective.

We take in modern IT technology to our mature technique to satisfy customers’ needs in a flexible way.

We are also highly evaluated for our in-house coherent system from planning, designing to mass production, or production of small lot quantity.

We offer just one prototype.

We offer thousand mass-products.

We have the ability to make the best suggestions

and serve the best products to the customers’ needs.

Mic-MDS Self-developing high- precision mold-tool at low cost

Advantages

- Decreases the number of mold-parts

- Unrestricted by work-size or lot amount of manufacturing parts

- Ensures equal durability with general mold-tools

- Decreases mold machining time

- Decreases mold material cost

- Decrease mold storing space

- educes setup by weight saving

- Compatible with general molds and MDS. Enables same setup method with general mold-tools by adopting simple setup-jigs.

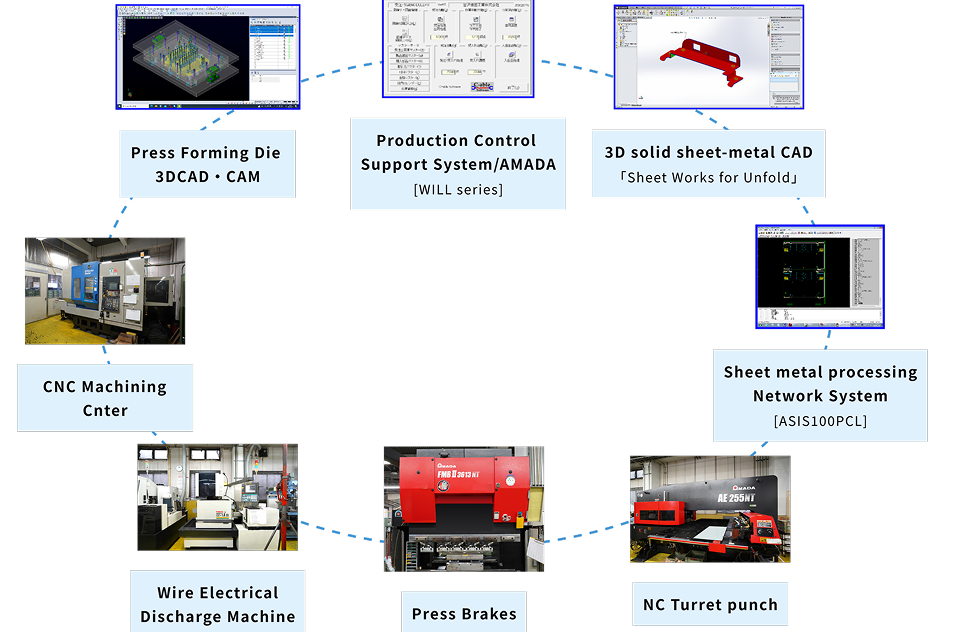

IT-based production management

Proactive approach to 5S Activity

- ①Organization(Seiri)

- ②Arrangement(Seiton)

- ③Cleaning(Seisou)

- ④Cleanliness(Seiketu)

- ⑤Breeding(Situke)

To put 5S Activity in practice is to develop as an organization carrying out what is ordinary for granted.We are all devoted to this 5S Activity which is targeting “products”, “information” as well as “people”.

This policy aims at developing operational infrastructure for operational efficiency, prevention of errors and accidents, and effective utilization of space.

The whole staff is working everyday with this policy at the core.